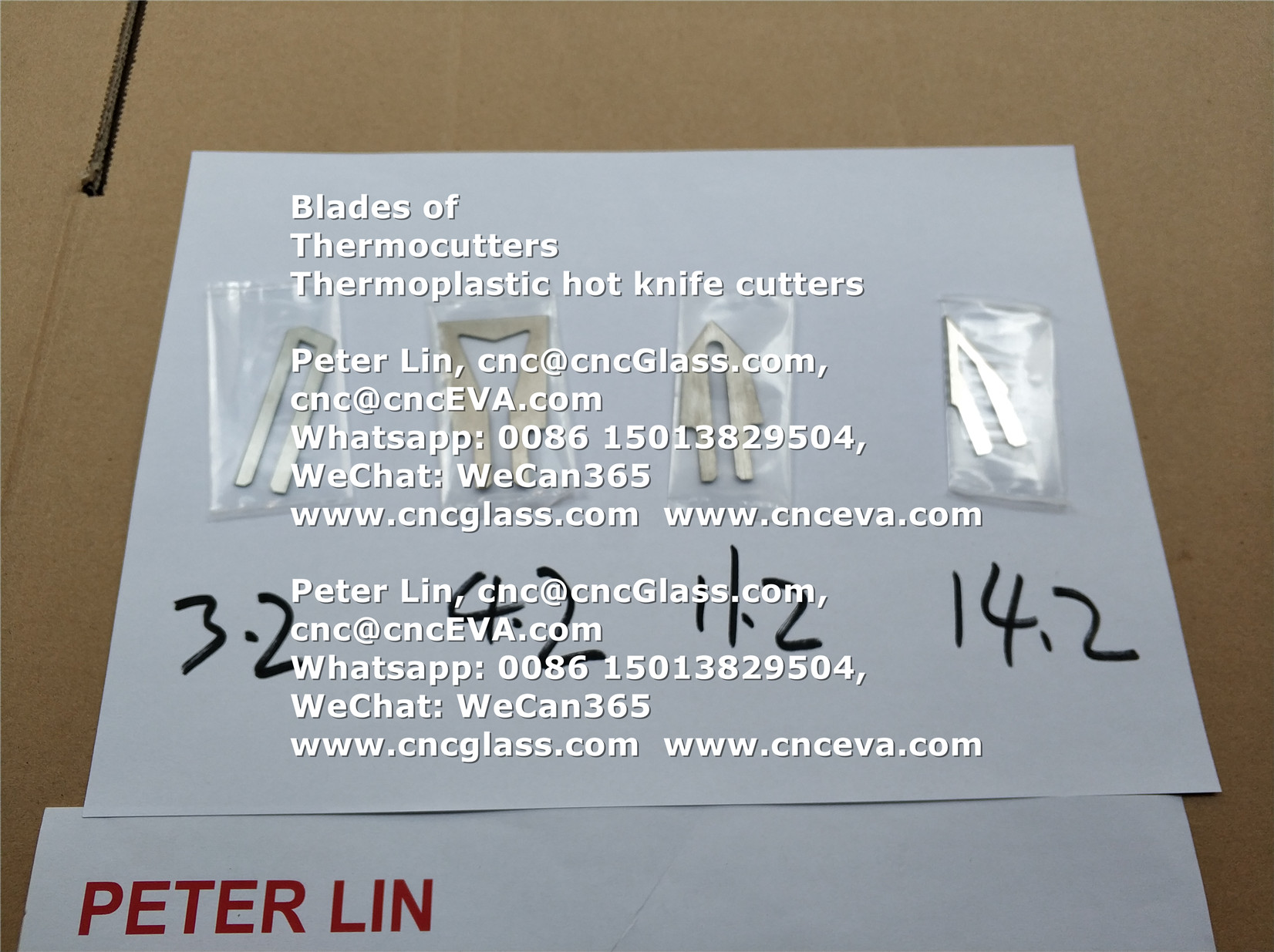

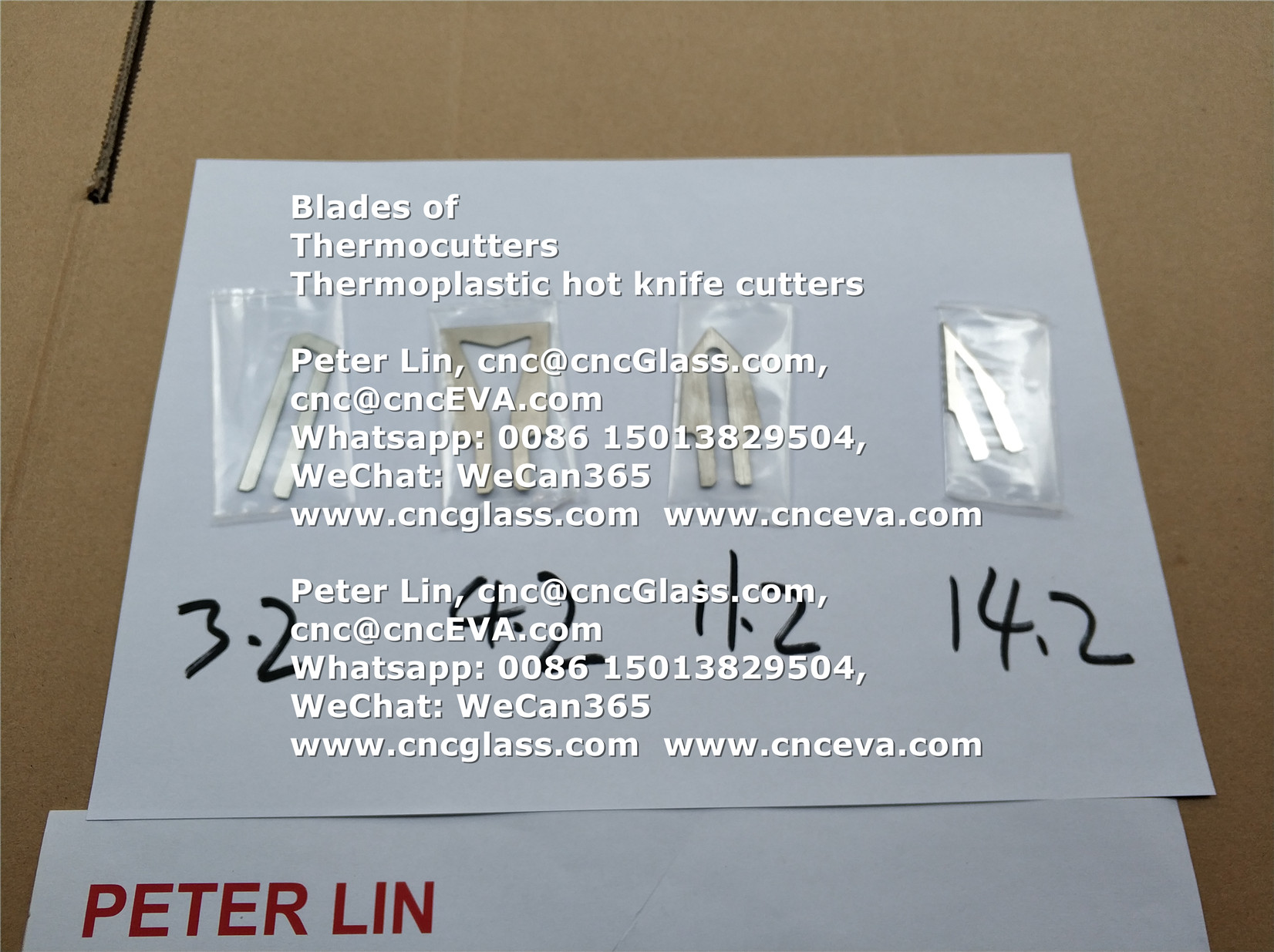

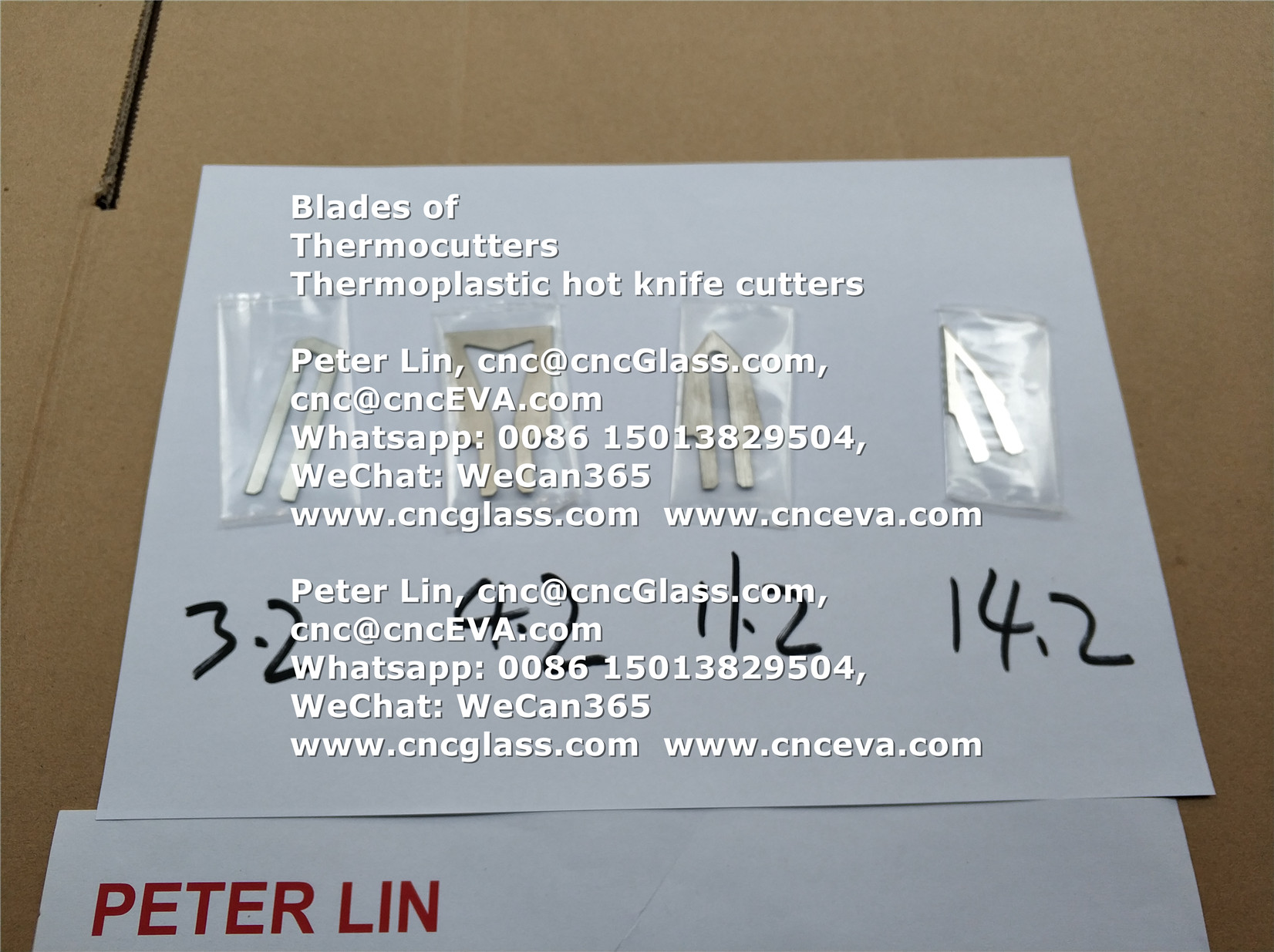

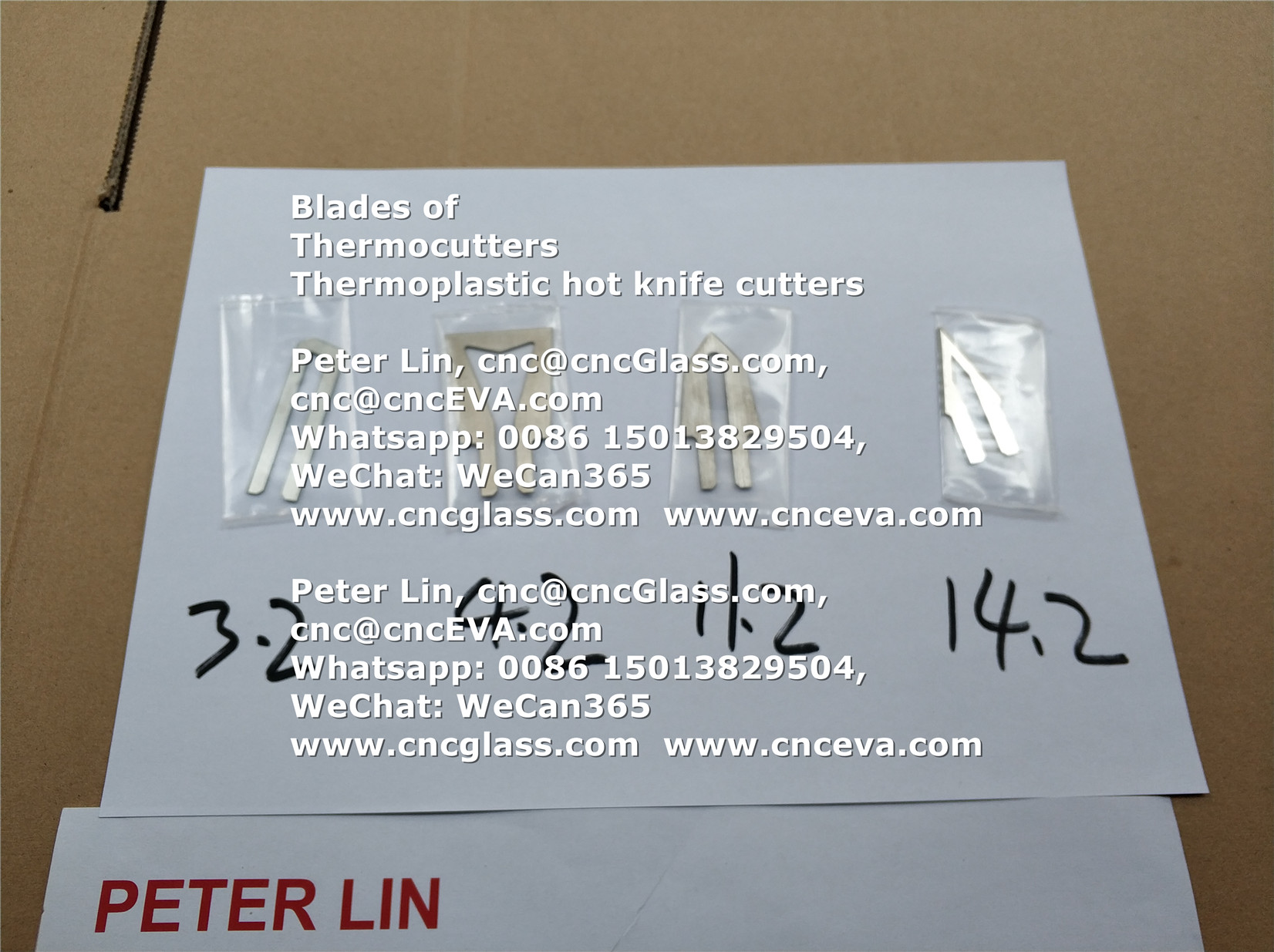

Blades of Thermocutters Thermoplastic hot knife cutters

Features:

• Can cut thermoplastic materials up to 5 inches thick

– depending on material density

• Blade heats up instantly

• Lightweight and dependable, these cutters always get the

job done

• Find the tool that is right for you – we currently offer 4

different blade types

Peter Lin, [email protected],

[email protected]

Whatsapp: 0086 15013829504,

WeChat: WeCan365

www.cncglass.com www.cnceva.com

Thermocutters aid in many types of construction projects that involve thermoplastics. Quickly terminate fiber optics, cut braided sleeving to size, trims tarps, or streamline any thin plastic application you can imagine. We supply a variety of blades and tools to help you with your solutions.

Choose the blade and cutter to suit your solution/application. Blades are designed to route heat along the cutting edge for smooth cutting. Before cutting material, the blade temperature will be between 200°F and 1400°F, depending on the thermocutter model and blade type. As the blade passes through the material it cools down. The blade temperature is directly affected by the properties of the material being cut – this will determine the cutting speed.

Peter Lin, [email protected],

[email protected]

Whatsapp: 0086 15013829504,

WeChat: WeCan365

www.cncglass.com www.cnceva.com